Harnessing the Power of Laser Cutters in Sheet Metal Prototyping

Sheet metal prototyping is a crucial stage in product development, permitting engineers and architects to test and refine their designs earlier than complete-scale manufacturing. Traditional prototyping techniques often contain time-eating procedures and excessive prices. However, with the appearance of laser cutting generation, sheet steel prototyping has gone through a full-size transformation.

In this article, we will delve into the benefits and packages of laser cutters in sheet steel prototyping, exploring how this advanced generation is revolutionizing the industry.

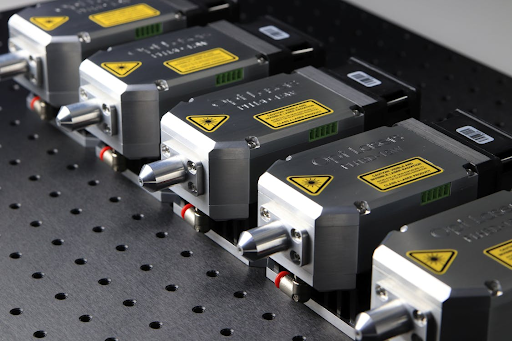

Understanding Laser Cutting Technology

Before discussing its utility in sheet steel prototyping, it is critical to comprehend the basics of laser reducing generation. Laser cutting utilizes an excessive-powered laser beam to exactly reduce via substances which include metallic, plastic, and timber. The laser beam is managed by a laptop-aided design (CAD) software, which directs it along the preferred reducing route with excellent accuracy. This method permits for intricate designs and unique cuts, making it ideal for prototyping programs.

Advantages of Laser Cutters in Sheet Metal Prototyping

Precision and Accuracy: Laser cutters offer unheard of precision in reducing sheet metal, taking into account the creation of complicated designs with tight tolerances. This stage of accuracy is crucial in prototyping, where even minor deviations can affect the capability and aesthetics of the very last product.

Rapid Prototyping: One of the most extensive advantages of laser cutters is their capacity to unexpectedly produce prototypes. Unlike conventional machining strategies, which may additionally require huge setup and tooling adjustments, laser cutting can quickly translate digital designs into physical prototypes, lowering time-to-marketplace and rushing up the product improvement cycle.

Versatility: Laser cutters are extraordinarily versatile tools that could accommodate an extensive range of materials and thicknesses. Whether running with stainless-steel, aluminum, or titanium, laser slicing era can handle diverse sheet metal materials easily, making it appropriate for prototyping numerous products across industries.

Cost-Effectiveness: While the preliminary funding in laser cutting equipment can be extensive, the long-term fee advantages of sheet metal prototyping with laser cutters are great. The efficiency and velocity of laser reduction translate to lower exertion charges and reduced material waste, in the long run mainly to fee savings through the years.

Design Flexibility: Laser cutting generation gives remarkable layout flexibility, permitting engineers and architects to iterate and refine their prototypes simply. Unlike conventional methods that can be confined through tooling constraints, laser cutters can accommodate complicated geometries and problematic patterns, permitting creative freedom in prototyping.

Applications of Laser Cutters in Sheet Metal Prototyping

Product Design and Development: Laser cutters play an essential role within the iterative system of product design and improvement. Engineers can quickly create prototypes to check shape, match, and function, bearing in mind fast iteration and refinement till the preferred layout is completed.

Proof of Concept: Laser-cut prototypes provide a tangible representation of conceptual thoughts, permitting stakeholders to visualize and compare the feasibility of a design idea. By creating functional prototypes early within the development manner, capability troubles may be identified and addressed earlier than moving to production.

Customization and Personalization: Laser cutting era enables customization and personalization of sheet metallic components, making it best for generating bespoke prototypes tailor-made to precise client requirements. Whether growing one-off prototypes or small-batch productions, laser cutters provide unrivaled flexibility in assembly customer demands.

Testing and Validation: Prototyping with laser cutters lets in for rigorous testing and validation of layout ideas beneath actual-international situations. Engineers can difficulty prototypes to various environmental elements, mechanical stresses, and performance checks to assess their durability, reliability, and functionality.

Pre-Production Tooling: Laser-reduce prototypes also can function as templates for the production of custom tooling and fixtures. By using laser-cut prototypes to validate tooling designs and production processes, manufacturers can reduce the chance of errors and optimize production performance.

Conclusion

Laser cutters have revolutionized the process of sheet metal prototyping, offering remarkable precision, speed, and flexibility. From product layout and improvement to customization and testing, laser reducing technology performs a critical function in bringing modern thoughts to existence. By harnessing the electricity of laser cutters in sheet metal prototyping, engineers and architects can accelerate the product development cycle, lessen prices, and in the end carry terrific products to market quicker than ever earlier than.